1. Vietnam Wet Processed Arabica Green Coffee – The most popular coffee in the world

Vietnam Wet Processed Arabica Green Coffee (Fully Washed): Arabica has an intense aroma, ethereal sour taste, slightly bitter taste, and sweet aftertaste, described as the fresh taste of the early morning, making the drinker unable to forget the taste of Vietnam Arabica once tried past.

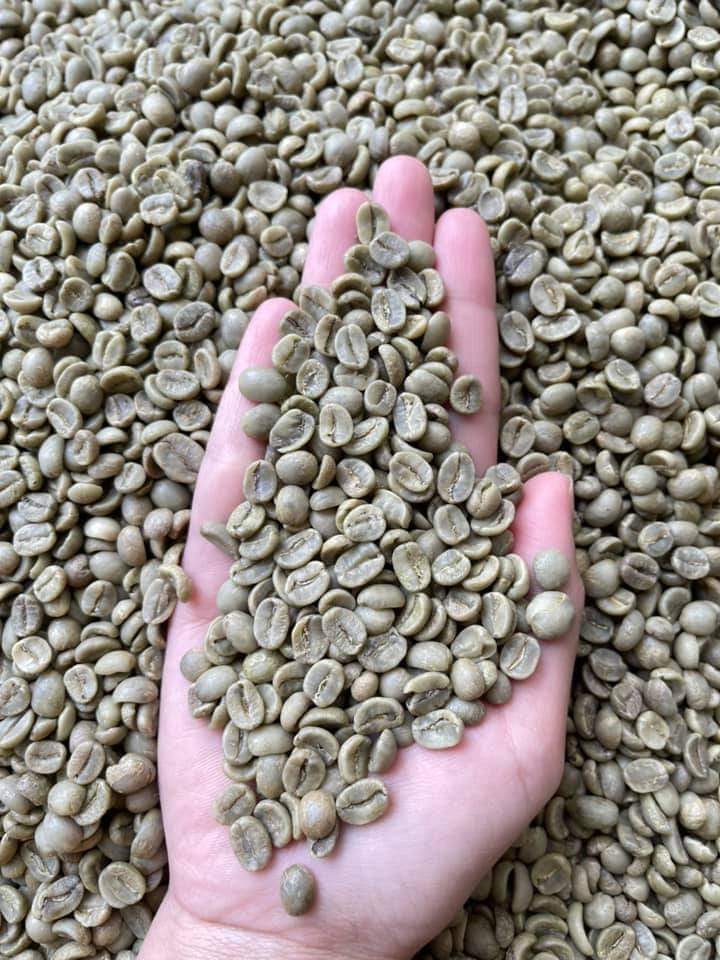

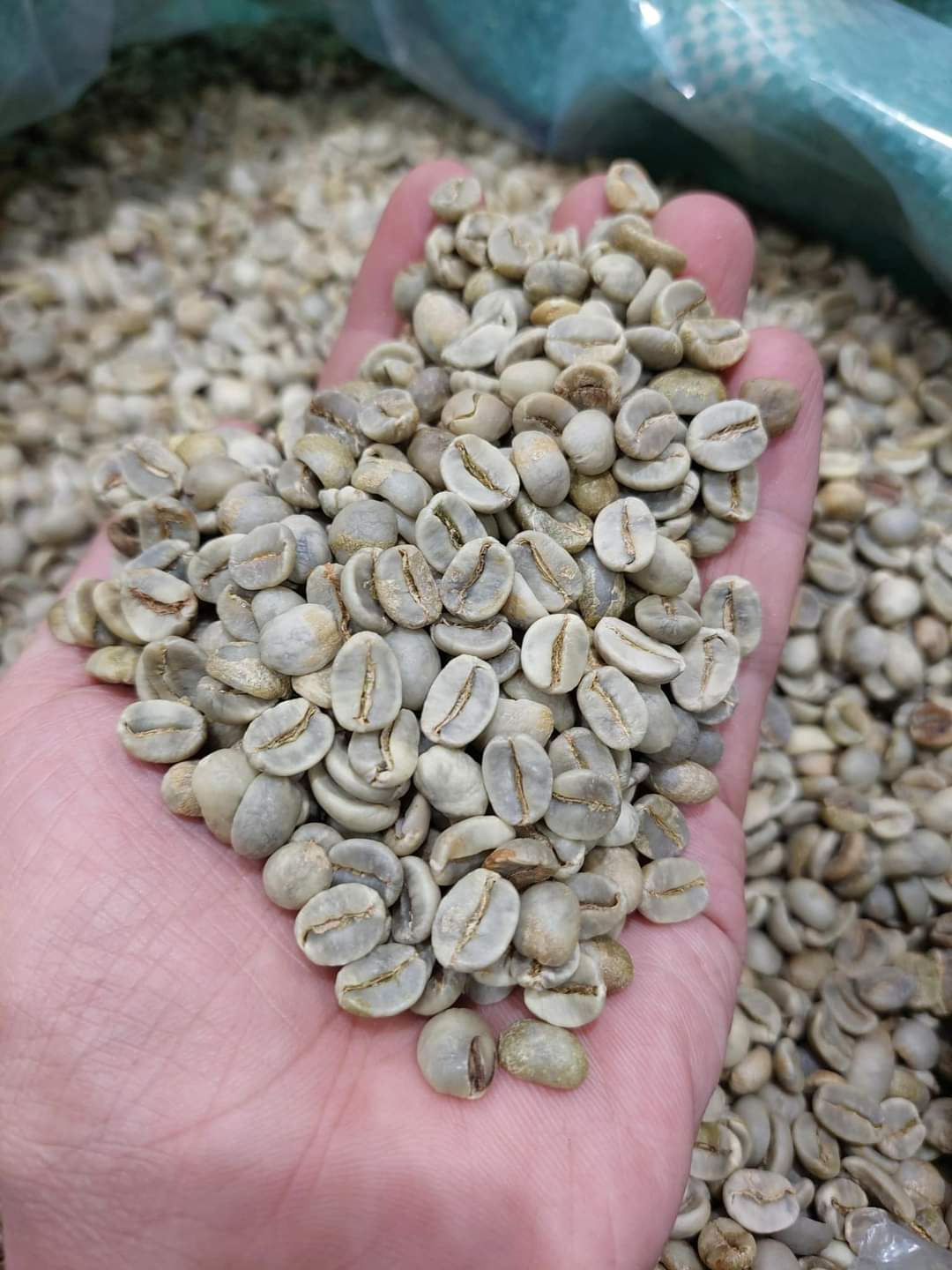

We choose the raw material of wet-processed green Arabica coffee. When done correctly, this processing method helps to ensure the intrinsic quality of the coffee beans, resulting in green coffee of uniform color and quality, avoiding defects that adversely affect the tasting quality.

Arabica is the most popular coffee in the world. In Vietnam, Arabica from the Vietnam region is famous for its delicious taste, rich flavor, and excellent quality. To get the best product, we have carefully collected and processed to preserve the original flavor of coffee beans.

Arabica has an intense aroma, ethereal sour taste, slightly bitter taste, and sweet aftertaste, described as the fresh taste of the early morning, making the drinker unable to forget the taste of Vietnam Arabica once tried past once.

Besides the enjoyment value, Arabica also has health benefits because they are low in caffeine, so they are completely healthy for the elderly and people with heart problems. In addition, Arabica does not cause insomnia, has the effect of slowing down aging and is suitable for women.

2. How to produce Arabica Fully Washed Processing in Vietnam?

Wet processing is more complicated than dry processing and is often applied to Arabica coffee. The main feature of damp processing is that the flesh between the beans and the coffee skin is removed before the coffee is dried.

This method requires specialized machinery and consumes a significant amount of water, so there must be a reasonable treatment process to ensure both safeties for the environment.

When done correctly, this processing method helps to ensure the intrinsic quality of the coffee beans, resulting in green coffee of uniform color and quality, avoiding defects that adversely affect the tasting quality. Coffee produced by wet processing is always of better quality and of higher commercial value.

The wet processing process mainly consists of 5 steps:

- First step: Cleanse impurities. After harvesting, no matter how careful it is, there is still a quantity of dry, unripe, or wormed coffee cherries that will reduce the quality of the coffee batch. In addition, small twigs, coffee leaves, rocks and dirt, and other impurities will be mixed in the coffee lot through the harvest. Preliminary processing, grading, and cleaning of ripe coffee cherries are essential and should be done soon after harvest and usually done by washing ripe coffee cherries in a bucket full of running water. The coffee then goes through a vibrating machine to screen the beans, which separates ripe and unripe cherries, large and small.

- The second step: This stage is done by a machine that rubs, peels, and removes the flesh and mucus from the coffee beans. After sorting, it is necessary to immediately rub the coffee berries to avoid affecting the quality of the coffee. This stage separates the skin, meat, mucus, and coffee beans, and the coffee is cleaned. This step makes an essential difference between the dry and wet processing methods.

- The third step: is the fermentation process. Since the pulp and mucilage of the fruit that is separated from the bean by mechanical means are often left around the coffee beans and will have an adverse effect on the quality of the coffee, further work must be done—cleaned by chemical means. Grain coffee beans are aged in large vats and left to ferment by natural enzymes and additional enzyme preparations. For most coffees, the mucus removal process takes 24 to 36 hours, depending on the thickness, temperature of the mucus layer, and concentration of enzymes. After fermentation, the mucus around the coffee beans loses its dense texture and is easily removed by water.

- Fourth step: Drying stage. After fermentation, coffee beans are washed with clean water, containing about 57% – 60% moisture content, and transferred to the drying stage. The drying process ends when the coffee moisture level is 12.5%. Coffee beans can be dried in a concrete yard or by electric drying. Sun exposure takes between 8 and 10 days, depending on ambient temperature and humidity. Dryer-dried coffee dries faster. However, the process must be carefully controlled to be satisfactory and economical without damaging the coffee quality.

- Fifth step: Storage. After drying, the parchment coffee will be stored and milled into green coffee before packing for export or being put into the roaster during the roasting process.